Catégorie

Fours de fusion d'aluminium et d'alliages d'aluminium

1. Description

☀ Le four utilise principalement des lingots d'aluminium, des matériaux recyclés, des matériaux recyclés, etc. comme matières premières. Il peut

Production de barres d'aluminium (série 1, série 3, série 6, série 8), lingots d'aluminium, barres d'aluminium et autres produits.

☀ Selon les exigences du client: four à ciel + four à isolation circulaire (pour la fusion), double chambre

Fours de fusion, fours de fusion rectangulaires inclinés, fours de fusion rectangulaires pour lingots ou barres. Les différents poêles ont

Différentes applications, détaillées dans le tableau des paramètres techniques.

☀ Le système de combustion de la fournaise offre de nombreuses options énergétiques.

☀ La structure en acier du four a été conçue avec de lourdes charges à l'esprit. Matériau réfractaire adopte une classe

La marque garantit une longue durée de vie.

☀ Le foyer utilise une conception de combustion à accumulation de chaleur et un contrôle automatique de la température PID. Il a une chaleur plus élevéeÉnergie

Le taux de conversion est élevé et économise 20 à 40% d'énergie par rapport aux systèmes de combustion traditionnels.

☀ La cuisinière est contrôlée par HMI + PLC, surveillance centralisée, affichage. Les paramètres techniques peuvent être lus et stockés,

Et l'écran tactile peut être modifié directement. Il est pratique et efficace.

☀ Adopte le four d'entraînement hydraulique, la technologie de mesure et de contrôle au laser pour assurer un contrôle stable du débit

Coulée de liquide d'aluminium.

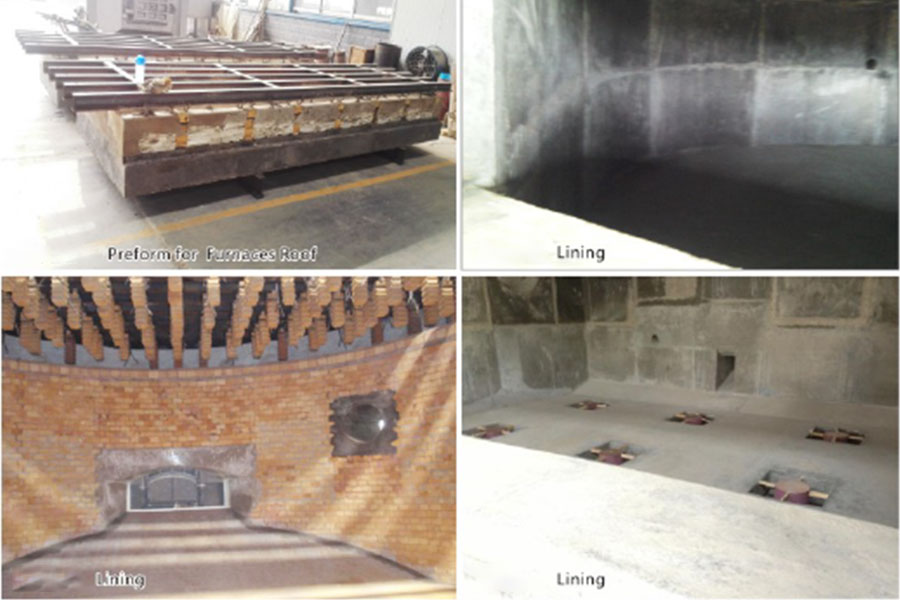

2. Images d'équipement

-------------------------- four à double chambre + four à isolation circulaire

- - fours rectangulaires inclinés ou fixes en alliage d'aluminium - - fours rectangulaires inclinés ou fixes pour lingots ou barres en alliage d'aluminium

3. Paramètres techniques

Indicateurs techniques | Four céleste + four à isolation circulaire | Four à deux chambres | Inclinaison rectangulaire des barres en alliage d'aluminium | Four incliné rectangulaire pour lingots ou barres en alliage d'aluminium |

Matériaux | A00 lingots d'aluminium, matériaux d'emballage réchauffés, petites quantités de déchets | A00 lingots d'aluminium, matériaux d'emballage réchauffés, petites quantités de déchets | A00 lingots d'aluminium, matériaux d'emballage réchauffés, déchets d'emballage, poteaux usagés | Déchets d'emballage, matériaux d'emballage réchauffés, déchets d'aluminium moulé concassé, déchets d'emballage légers |

Énergie | Gaz naturel, GPL, mazout lourd, diesel, gaz | Gaz naturel, GPL, mazout lourd, diesel, gaz | Gaz naturel, GPL, mazout lourd, Diesel | Gaz naturel, GPL, mazout lourd, diesel, gaz |

Type de four | Cylindre vertical, | Cylindre vertical / cylindre carré | Inclinaison rectangulaire | Fixation / inclinaison rectangulaire |

Centre de produits | Barre en aluminium | Barre en aluminium | Barres en aluminium, barres en aluminium | Lingots d'alliage, lingots d'aluminium, tiges d'aluminium, bandes de tôle d'aluminium |

Logo de la boutique | ||||

Capacité | 5T / H - 10T / h | 5T / H - 10T / h | 10 tonnes - 35 tonnes 7 - 10T / h | 10 - 100T 4 - 20t / h |

5. Démonstration de l'application

☀ Il peut être équipé de deux fours thermiques. Le raffinage et l'évacuation des scories se feront alternativement dans un four d'isolation pour assurer

Coulée continue d'aluminium aqueux;

☀ Les fours rectangulaires peuvent être utilisés dans les usines où la demande est moindre. La fusion, le raffinage et l'évacuation des scories seront effectués dans ce four.

Continuez ce processus quand il est vide.

☀ Equipé d'un système d'agitation en aluminium, d'un système de dégazage en ligne et d'un système de filtration, il peut être utilisé pour le raffinage

Composition de l'alliage d'aluminium et dégraissage avant coulée;

☀ Peut être équipé de la ligne de production de laminage en continu de coulée continue pour produire des barres en aluminium, machine de lingotière continue pour produire des barres en aluminium

Production de lingots d'aluminium et de machines de coulée de barres, production de barres d'aluminium;